-

Study on Steel-Plastic Interface Bond Strength of Steel Wire Skeleton Plastic Composite Pipes ——High-Pressure Water Transmission Applications Based on GB/T 32439 Standard

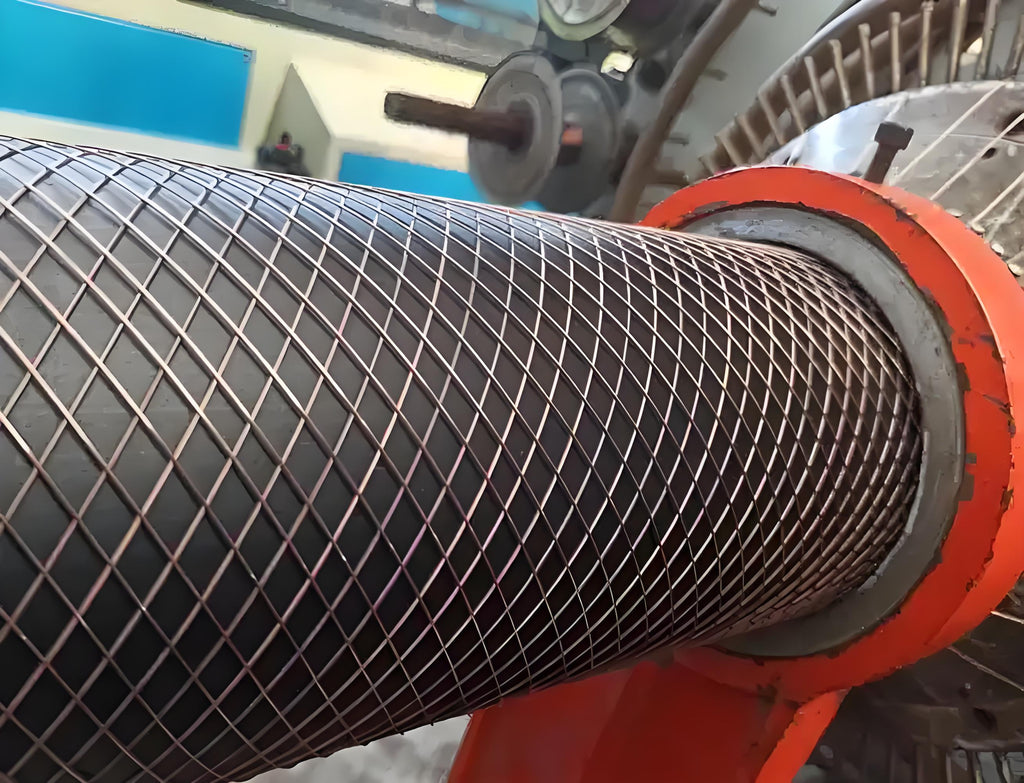

1. Research Background Steel Wire Skeleton Plastic Composite Pipes (SRTP), with a "high-strength steel skeleton + HDPE" structure (Figure 1), are increasingly used in urban water and gas networks. While their ring stiffness reaches SN12.5, interface bond failures account for 53% of leaks (2024 CPPIA data), especially under high pressure (>1.6MPa). 2. Core Issue: Interface Failure Mechanism 2.1 Bond Failure Modes Through universal testing machines (GB/T 18369-2008) and SEM, three failure modes were identified: Interface debonding (68%): Bond strength <3.5MPa Plastic tearing (22%): Insufficient HDPE strength Steel corrosion (10%): Electrochemical corrosion at interface gaps 2.2 Key Influencing Parameters Parameter GB Requirement Field Measurement Influence Steel plating thickness (μm) ≥85... -

Pressure Resistance and Long-Term Reliability of PVC-U Drinking Water Pipes ——Stress Analysis and Life Prediction Based on GB/T 10002.1 Standard

1. Research Background PVC-U (Unplasticized Polyvinyl Chloride) pipes are ideal for drinking water supply due to their high strength, corrosion resistance, and no plasticizer migration (Figure 1). However, in high-pressure scenarios (high-rises, long-distance 输水): 50-year hydrostatic strength compliance is only 78% (GB/T 6111-2018) - 爆裂 rate of dn200mm pipes is 0.6 times/100km·year (domestic water company data) 2. Core Issue: Pressure Failure Mechanism 2.1 Failure Stages Through full-scale burst testing and creep testing, failures occur in three stages:  Elastic stage (0-10 years): Strain <2%, linear stress-strain Plastic creep stage (10-30 years): Strain rate 0.01%/year, crystallinity decrease Fracture stage (>30 years): Brittle fracture due to stress concentration 2.2 Key Parameters Parameter... -

Hydraulic Performance Optimization of Perforated Steel-Belt PE Composite Pipes for Drainage ——Cooperative Design of Infiltration and Drainage for Sponge City LID Facilities

1. Research Background Perforated steel-belt PE composite pipes, with a "steel reinforcement + HDPE matrix + regular perforations" structure (Figure 1), are core components for sponge city stormwater infiltration systems. Compared to ordinary PE perforated pipes, their ring stiffness increases by 50%, but engineering issues exist: Perforation rate >25% causes 22% strength reduction (GB/T 19472.2 critical value) 41% blockage rate after 3 years due to sediment (2024 MOHURD report) 2. Core Issue: Perforation Structure Conflict 2.1 Performance Parameter Conflicts Parameter Infiltration Requirement Structural Requirement Traditional Design Conflict Perforation rate (%) ≥20 ≤25 Performance inflection at 22-24% Hole diameter (mm) 8-12 (for infiltration)...