-

In-depth analysis of impact-resistant materials for tunnel escape pipe--Scientific decision-making guide for engineering selection

First, the life and death of 0.8 seconds: the engineering code of anti-impact performance(Dynamic chart: impact energy absorption curve of different materials) 1.1 Impact dynamics revealedWhen a 1-ton weight hits a pipe at a speed of 9m/s, the material needs to complete the energy transformation within 0.8 seconds: Elastic deformation stage (0-0.2 seconds): molecular chain stretching to absorb the initial kinetic energy Plastic deformation stage (0.2-0.5 seconds): the microstructure of the material undergoes orderly destruction. Fracture failure stage (0.5-0.8 sec): crack extension leading to structural collapse 1.2 Temperature-impact toughness Rubik's cube diagram(Three-dimensional model to show the... -

Tunnel Escape Pipelines: Technical Specifications, Scientific Principles, and Critical Challenges

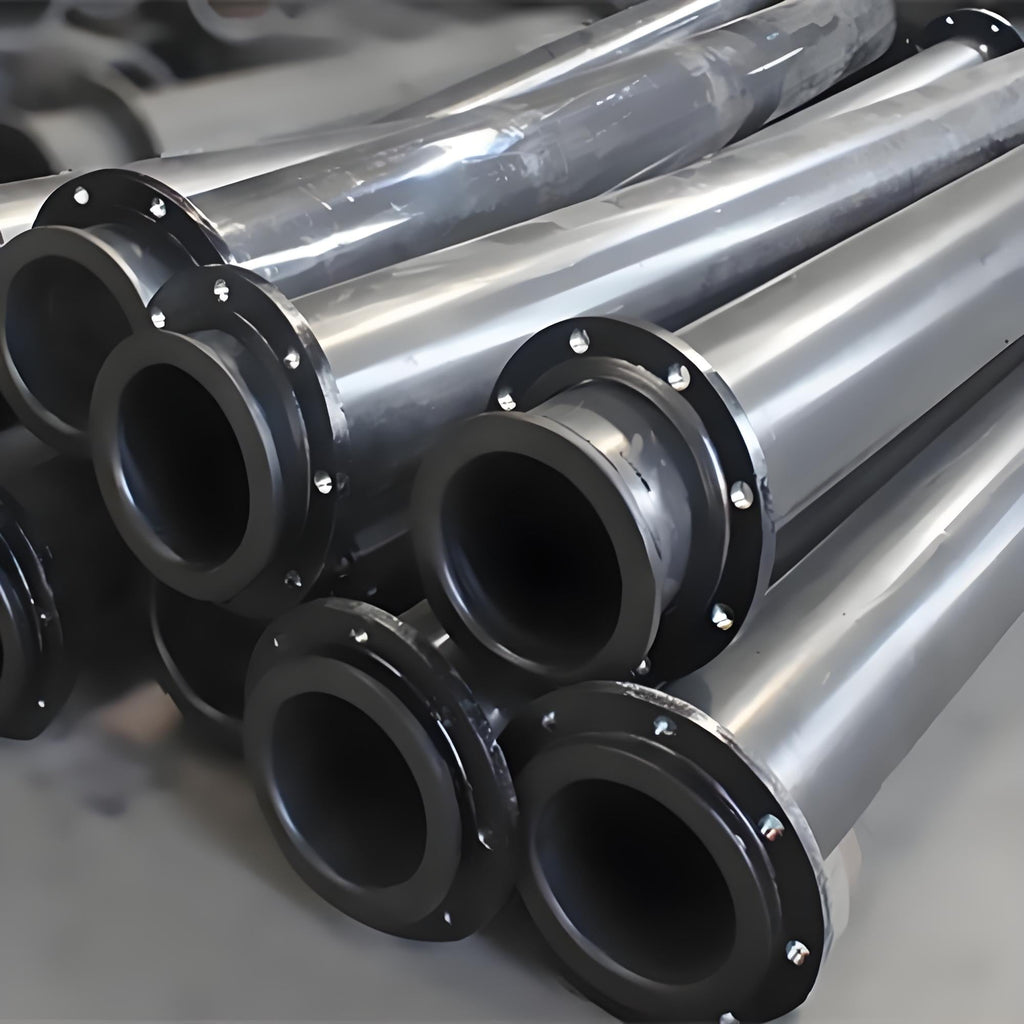

Tunnel Escape Pipelines: Technical Specifications, Scientific Principles, and Critical Challenges As vital "lifelines" in tunnel engineering, escape pipeline design directly impacts safety during construction and operation. This article systematically examines scientific principles, engineering practices, and existing challenges through technical standards, material performance data, and case studies. --- ## I. Material Properties and Structural Design Fundamentals ### 1. **Comparative Mechanical Properties of Core Materials** **Ultra-High Molecular Weight Polyethylene (UHMWPE)** dominates the market with: - Impact strength: 83.5 KJ/m² - Yield strength: 26.03 MPa - Density: 0.93-0.94 g/cm³ (1/8 the weight of steel pipes) - Molecular weight: >2.5... -

Ultra-High Molecular Weight Polyethylene (UHMWPE) Wear-Resistant Pipe: A Comprehensive Guide

Ultra-High Molecular Weight Polyethylene (UHMWPE) Wear-Resistant Pipe: A Comprehensive Guide 1. Material Properties: The "Superpowers" of UHMWPE Molecular Structure & Core AdvantagesUHMWPE boasts a molecular weight of 1.5–8 million (vs. 20k–300k for standard PE), with ultra-long molecular chains forming an interlocking network that delivers: Exceptional Wear Resistance: 4–7x more wear-resistant than carbon steel, ideal for abrasive media like ores and slurries. Self-Lubrication: Friction coefficient of 0.07–0.11 (comparable to PTFE), reducing energy loss during material transport. Impact Resistance: 10x higher impact strength than nylon 66, maintaining flexibility even at -269°C. Chemical Resistance: Resists acids, alkalis, and organic solvents (except strong oxidizers like...